Construction Site Risk Assessment: Key Hazards and Controls

Construction work is one of the most hazardous industries worldwide. With activities like working at heights, lifting heavy loads, operating machinery, and handling electrical systems — the potential for accidents is high.

Every year, thousands of construction workers suffer injuries that could have been prevented through a proper Construction Site Risk Assessment.

A well-structured risk assessment not only helps identify and control hazards but also ensures legal compliance and fosters a culture of safety across the project.

In this comprehensive guide, we’ll explore:

- What is a Construction Site Risk Assessment

- Why it’s important

- Common hazards in construction

- Control measures and preventive actions

- Step-by-step method to perform a risk assessment

- Free downloadable template

What is a Construction Site Risk Assessment?

A Construction Site Risk Assessment is a systematic process used to identify hazards, evaluate associated risks, and implement measures to reduce those risks to acceptable levels.

It forms the foundation of HIRA (Hazard Identification and Risk Assessment) and ensures that every activity is performed safely and efficiently.

Definition

“Risk assessment is the process of identifying hazards, analyzing the likelihood and severity of harm, and determining appropriate control measures to prevent injury or ill health.”

Legal Requirements for Construction Risk Assessment

Risk assessment is a legal requirement under many international and national regulations.

Key Legal References:

- OSHA (29 CFR 1926): Employers must identify and control workplace hazards before work begins.

- UK – Construction (Design and Management) Regulations 2015 (CDM): Requires risk assessment and safe systems of work.

- India – Factories Act 1948 & BOCW Act 1996: Mandates hazard control measures and worker protection on construction sites.

- ISO 45001: International standard for occupational health and safety management systems.

Failure to comply with these laws can result in penalties, work stoppages, or severe incidents.

Objectives of Construction Risk Assessment

A construction site risk assessment aims to:

- Identify all potential hazards at the site.

- Evaluate the level of risk associated with each hazard.

- Determine effective control measures to eliminate or reduce risk.

- Prevent accidents, injuries, and property damage.

- Promote a proactive safety culture.

- Ensure compliance with safety laws and standards.

The 5 Steps of a Construction Site Risk Assessment

Every safety professional should follow these five essential steps when performing a site risk assessment:

Step 1: Identify Hazards

Inspect the worksite and list all potential hazards. Think about:

- Activities being performed

- Equipment and materials used

- Environmental conditions

- Human behavior

Examples of hazards:

- Falling from height

- Electrical shock

- Struck-by incidents

- Excavation collapse

- Fire and explosion

- Exposure to dust and chemicals

Tip: Conduct walk-around inspections with supervisors and workers to identify hidden hazards.

Step 2: Decide Who Might Be Harmed and How

Consider all categories of people who might be at risk:

- Site workers

- Subcontractors

- Visitors

- Engineers and inspectors

- Nearby public or pedestrians

Example:

During concrete pouring, workers may be exposed to splashes (chemical hazard) and heavy load movement (physical hazard).

Step 3: Evaluate the Risks and Decide on Controls

Use a Risk Matrix to determine the severity and likelihood of harm.

| Severity (S) | Likelihood (L) | Risk Rating (S × L) | Action |

|---|---|---|---|

| 1 = Minor Injury | 1 = Rare | 1–4 = Low | Maintain controls |

| 2 = Moderate Injury | 2 = Possible | 5–9 = Medium | Improve controls |

| 3 = Major Injury | 3 = Likely | 10–15 = High | Immediate action required |

| 4 = Fatality | 4 = Almost Certain | 16+ = Very High | Stop work immediately |

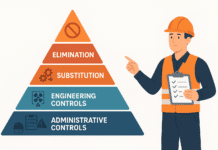

Apply control measures based on the Hierarchy of Controls:

- Elimination

- Substitution

- Engineering Controls

- Administrative Controls

- PPE

Step 4: Record the Findings

Document:

- Hazards identified

- People at risk

- Control measures implemented

- Responsible persons and deadlines

A written record helps in legal compliance and future reviews.

Step 5: Review and Update

Risk assessments are living documents. They must be reviewed:

- After incidents or near misses

- When work conditions or scope change

- Periodically (e.g., monthly or quarterly)

Common Hazards on Construction Sites (and Their Controls)

Below are the key construction hazards along with examples of control measures for each.

Working at Height

Hazards:

- Falls from scaffolds, ladders, or roofs.

- Falling objects hitting workers below.

Controls:

Use full-body harnesses and lifelines.

Provide guardrails and toe boards.

Inspect scaffolds regularly.

Use proper ladder angle (4:1 ratio).

Barricade drop zones below elevated work areas.

Electrical Hazards

Hazards:

- Contact with live wires.

- Poorly maintained tools.

- Overloaded circuits.

Controls:

Conduct pre-use inspection of electrical tools.

Implement Lockout/Tagout (LOTO) system.

Use only certified extension cords and plugs.

Keep electrical panels closed and labeled.

Maintain safe clearance from overhead power lines.

Excavation and Trenching

Hazards:

- Collapse of trench walls.

- Asphyxiation due to lack of oxygen.

- Contact with underground utilities.

Controls:

Inspect trenches daily by a competent person.

Use shoring, shielding, or sloping.

Provide safe access ladders every 25 feet.

Keep spoil piles at least 2 feet from trench edge.

Monitor air quality inside deep excavations.

Lifting and Rigging Operations

Hazards:

- Load dropping or swinging.

- Equipment failure.

- Personnel struck or crushed.

Controls:

Use certified lifting tackles and slings.

Conduct pre-lift inspection.

Only trained and certified crane operators allowed.

Establish exclusion zones.

Use taglines to control suspended loads.

Hot Work (Welding, Cutting, Grinding)

Hazards:

- Fire or explosion.

- Burns or eye injury.

- Fume inhalation.

Controls:

Obtain a Hot Work Permit.

Keep fire extinguishers nearby.

Use flame-resistant curtains or shields.

Ensure adequate ventilation.

Wear appropriate PPE — welding helmet, gloves, aprons.

Manual Handling and Ergonomic Hazards

Hazards:

- Back injuries from lifting heavy loads.

- Muscle strain or fatigue.

Controls:

Use mechanical aids (trolleys, hoists).

Train workers on correct lifting techniques.

Rotate tasks to prevent fatigue.

Store heavy materials at waist height.

Housekeeping and Slips/Trips

Hazards:

- Slippery floors.

- Cluttered pathways.

- Unsecured cables.

Controls:

Maintain daily housekeeping.

Use proper waste bins and material stacking.

Provide slip-resistant flooring where possible.

Ensure adequate lighting.

Chemical and Dust Exposure

Hazards:

- Inhalation of cement dust or silica.

- Skin contact with chemicals like paint or thinner.

Controls:

Provide MSDS (Material Safety Data Sheets).

Use dust extraction systems.

Workers to wear respirators and gloves.

Store chemicals in labeled containers.

Noise and Vibration

Hazards:

- Hearing loss from prolonged exposure to noisy equipment.

- Vibration-related injuries from hand tools.

Controls:

Conduct noise level assessments.

Use hearing protection (earmuffs, plugs).

Maintain and lubricate tools.

Implement job rotation.

Fire Hazards

Hazards:

- Sparks from welding.

- Electrical short circuits.

- Improper fuel storage.

Controls:

Store flammable materials separately.

Install fire extinguishers and alarms.

Conduct fire drills periodically.

Prohibit smoking near fuel areas.

Construction Site Risk Assessment Template (Example)

| Activity | Hazard | Risk | Control Measures | Risk Level | Responsible |

|---|---|---|---|---|---|

| Working at Height | Fall from scaffold | Fatal injury | Guardrails, harness, supervision | High | Site Engineer |

| Hot Work | Fire and burns | Major injury | Permit to work, fire blanket | Medium | HSE Officer |

| Excavation | Collapse of wall | Fatal injury | Shoring, inspection | High | Site Supervisor |

| Electrical Work | Electric shock | Fatal | LOTO, insulated tools | High | Electrician |

| Material Handling | Musculoskeletal injury | Medium | Training, use of lifting aids | Medium | Workers |

Key Roles and Responsibilities

| Role | Responsibilities |

|---|---|

| Project Manager | Ensure overall safety compliance and provide resources. |

| Safety Officer | Conduct risk assessments and site inspections. |

| Supervisor | Implement control measures and brief workers. |

| Workers | Follow safety instructions and report hazards. |

| HSE Committee | Review incidents, monitor performance, and suggest improvements. |

Construction Site Risk Review Frequency

| Action | Frequency | Person Responsible |

|---|---|---|

| Site Risk Assessment Review | Monthly | Safety Officer |

| Equipment Inspection | Daily | Operator |

| Scaffold and Ladder Inspection | Weekly | Supervisor |

| Fire Drill | Every 6 months | HSE Officer |

| Toolbox Talk | Daily | Supervisor |

| Full Site Audit | Quarterly | HSE Manager |

Real-Life Example

Case:

A worker fell from an incomplete scaffold because guardrails were not installed.

Root Cause:

- Risk assessment not updated after scaffold modification.

- Lack of supervision.

Corrective Measures:

- Review and update HIRA before every site modification.

- Conduct re-inspection after scaffolding changes.

- Reinforce training on fall protection and safe access.

Result:

Zero fall-related incidents recorded in the next six months.

Benefits of Construction Site Risk Assessment

✔️ Reduced accidents and downtime

✔️ Improved productivity and morale

✔️ Legal compliance and client confidence

✔️ Enhanced company reputation

✔️ Stronger safety culture

Documentation Required

Maintain the following documents at the site:

- HIRA and risk assessment records

- Daily inspection checklist

- Permit-to-work forms

- Incident/near-miss reports

- Toolbox talk attendance sheets

- Fire and emergency plan

- Safety training records

Internal Links

- Common Mistakes in HIRA and How to Avoid Them

- Fire Risk Assessment in the Workplace – Complete Guide

- Demolition Safety Checklist | Free Template

- Top 10 Common Errors During Risk Assessments and How to Avoid Them

- Internal vs External Audits: Best Practices and Pitfalls for Safety Professionals

External References

Conclusion

A Construction Site Risk Assessment is not just a safety document — it’s the blueprint for protecting lives, equipment, and property on site.

By identifying hazards early and applying suitable controls, construction teams can work safely, meet deadlines, and maintain compliance.

“Safety doesn’t happen by accident — it starts with a risk assessment.”

Performing regular and detailed risk assessments transforms safety from a compliance task into a core value of your organization.