5 Levels of Risk Control (Hierarchy of Controls) Explained

Every workplace, from construction sites to manufacturing plants, is full of potential hazards — electrical, mechanical, chemical, ergonomic, or biological. To manage these risks effectively, safety professionals follow a structured framework called the Hierarchy of Controls.

This concept is the foundation of modern occupational health and safety management. It helps determine the most effective ways to eliminate or reduce hazards before they cause harm.

In this article, you’ll learn:

- What the Hierarchy of Controls means

- The 5 levels of risk control

- How each level works (with practical examples)

- Why relying only on PPE is not enough

- How to apply the hierarchy in real-world safety management

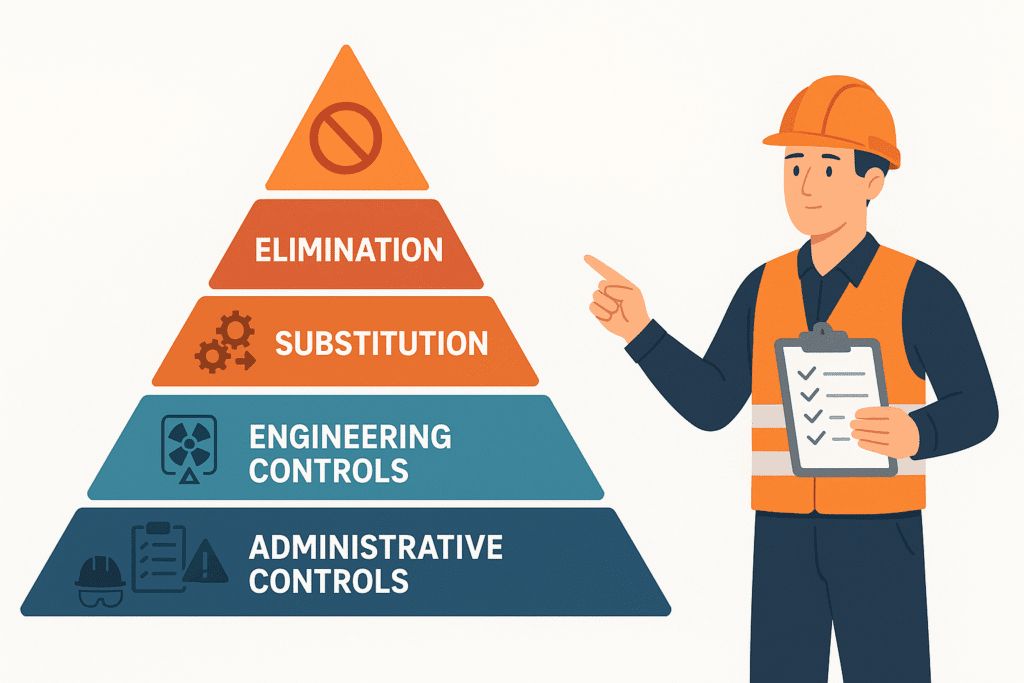

What is the Hierarchy of Controls?

The Hierarchy of Controls is a systematic approach used to manage and minimize workplace hazards. It ranks control methods from most effective to least effective based on their ability to eliminate or reduce risk.

Definition

“The Hierarchy of Controls is a framework that prioritizes hazard control measures based on their effectiveness in reducing risk — starting from elimination to personal protective equipment (PPE).”

It’s an essential part of risk assessment (HIRA, JSA, or RA) and a core principle in international safety standards such as ISO 45001 and OSHA 29 CFR 1910.

The 5 Levels of Risk Control

The Hierarchy of Controls includes five levels, arranged from the most reliable and permanent solution to the least effective and temporary measure:

- Elimination – Remove the hazard completely.

- Substitution – Replace the hazard with a safer alternative.

- Engineering Controls – Isolate people from the hazard.

- Administrative Controls – Change the way people work.

- Personal Protective Equipment (PPE) – Protect workers with equipment.

Let’s explore each level in detail.

Level 1: Elimination (Most Effective)

Definition:

Elimination means completely removing the hazard from the workplace so that it no longer exists.

It’s the most effective form of risk control because it permanently eradicates the risk source.

Example Scenarios

- Using a pre-fabricated steel structure instead of on-site welding (eliminates hot work hazards).

- Designing buildings to allow natural lighting instead of using portable lights (removes electrical hazard).

- Removing the need to work at height by assembling items on the ground before lifting.

Benefits

Completely removes risk.

No further control required.

Long-term and cost-effective solution.

Limitations

May not be feasible for all processes.

Could require redesign or high initial cost.

Tip: Always ask — “Can this task or material be eliminated altogether?”

Level 2: Substitution

Definition:

Substitution means replacing a hazardous process, material, or equipment with something safer.

It doesn’t eliminate the hazard but reduces the risk significantly.

Example Scenarios

- Using water-based paint instead of solvent-based paint to reduce fumes.

- Replacing diesel forklifts with electric forklifts to reduce emissions.

- Using battery-powered tools instead of corded ones to eliminate tripping hazards.

Benefits

Reduces exposure to hazardous substances or activities.

Often requires minimal procedural change.

Limitations

The substitute might introduce new risks (e.g., electric forklift charging hazards).

Requires compatibility testing before implementation.

Tip: Conduct a comparative risk assessment before substitution.

Level 3: Engineering Controls

Definition:

Engineering controls involve designing physical barriers or modifications to isolate people from hazards.

This approach doesn’t eliminate the hazard but prevents worker exposure through design improvements.

Example Scenarios

- Installing machine guards on moving parts.

- Using local exhaust ventilation (LEV) to remove welding fumes.

- Installing noise barriers around loud equipment.

- Adding safety interlocks or emergency stop switches on machinery.

Benefits

Reduces human dependency — built into equipment or systems.

Provides consistent protection.

Limitations

Can be costly to install and maintain.

May require technical expertise for design and monitoring.

Tip: Engineering controls are most effective when combined with regular maintenance and supervision.

Level 4: Administrative Controls

Definition:

Administrative controls reduce risk by changing the way people work rather than modifying the hazard itself.

They rely on procedures, training, supervision, and scheduling to minimize exposure.

Example Scenarios

- Developing Standard Operating Procedures (SOPs) for high-risk jobs.

- Rotating workers to minimize repetitive strain or chemical exposure.

- Signage and safety posters to warn about hazards.

- Conducting Toolbox Talks (TBTs) and refresher training.

- Implementing Permit-to-Work systems for hot work, confined space, or electrical tasks.

Benefits

Quick and inexpensive to implement.

Improves safety awareness and accountability.

Limitations

Dependent on human behavior and supervision.

Not a permanent solution.

Tip: Use administrative controls to support, not replace, higher levels of control.

Level 5: Personal Protective Equipment (PPE)

Definition:

PPE includes clothing and equipment designed to protect workers from specific hazards when other control measures are not sufficient.

It’s the last line of defense — used only when risks can’t be controlled by higher-level methods.

Example Scenarios

- Helmets and harnesses for working at height.

- Gloves and aprons for chemical handling.

- Safety goggles and face shields for grinding or cutting.

- Hearing protection in high-noise zones.

- Respirators in dusty or fume-prone environments.

Benefits

Provides immediate, individual protection.

Inexpensive compared to engineering solutions.

Limitations

Relies heavily on worker compliance.

Does not eliminate hazards — only reduces impact.

Requires continuous maintenance, training, and replacement.

Tip: Always choose PPE certified to international standards (EN, ANSI, IS, etc.).

Hierarchy of Controls — Summary Table

| Level | Control Type | Effectiveness | Example |

|---|---|---|---|

| 1 | Elimination | ⭐⭐⭐⭐⭐ | Remove need to work at height |

| 2 | Substitution | ⭐⭐⭐⭐ | Use non-toxic chemicals |

| 3 | Engineering Controls | ⭐⭐⭐ | Install guard rails or LEV systems |

| 4 | Administrative Controls | ⭐⭐ | Implement SOPs and safety training |

| 5 | PPE | ⭐ | Provide helmets, gloves, goggles |

✅ Remember: Always implement controls starting from top to bottom, not the other way around.

Practical Example – Applying Hierarchy of Controls

Let’s take the example of welding work inside a confined space:

| Step | Control Level | Applied Measure |

|---|---|---|

| Elimination | Cancel hot work and use mechanical connections instead. | |

| Substitution | Use low-fume welding rods or cold bonding adhesives. | |

| Engineering Controls | Install local exhaust ventilation, monitor gas levels. | |

| Administrative Controls | Implement confined space entry permit, assign standby man. | |

| PPE | Provide respirators, gloves, goggles, and flame-resistant clothing. |

As seen above, the goal is to control the hazard at the highest possible level first — before relying on PPE.

Why PPE Alone is Not Enough

Many workplaces make the mistake of focusing solely on PPE. However, PPE is the least effective because:

- It depends entirely on correct use by the worker.

- It does not remove the hazard.

- It can fail due to wear, poor maintenance, or incorrect fitting.

Example:

Wearing a helmet won’t stop a falling brick — but installing a toe board and netting (engineering control) will prevent it from falling in the first place.

Tip: Always consider PPE as a supplementary measure, not a standalone solution.

The Hierarchy of Controls in Risk Assessment

When conducting a HIRA (Hazard Identification and Risk Assessment), after identifying risks, the hierarchy of controls helps decide:

- Which control measures to apply first.

- Which risks require urgent attention.

- Whether residual risk is acceptable.

Residual Risk = Remaining risk after controls are implemented.

Auditors and inspectors often verify that the correct hierarchy has been applied during safety reviews.

Integration with ISO 45001

ISO 45001:2018 (Occupational Health & Safety Management Systems) emphasizes a risk-based approach, where the hierarchy of controls is a key requirement under:

- Clause 8.1.2 – Hierarchy of Controls:

Organizations must eliminate hazards and reduce OH&S risks by applying controls in the following order:- Elimination

- Substitution

- Engineering Controls

- Administrative Controls

- PPE

Tip: ISO auditors often ask for examples of control hierarchy implementation during certification audits.

Implementation Checklist

Use this quick checklist when applying the hierarchy of controls:

| Question | Yes / No |

|---|---|

| Can the hazard be completely eliminated? | |

| Can it be replaced with a safer alternative? | |

| Can engineering solutions isolate the hazard? | |

| Have administrative procedures been implemented? | |

| Has proper PPE been provided and used correctly? | |

| Are all controls monitored for effectiveness? | |

| Are residual risks acceptable and documented? |

📄 Download this checklist (Word/PDF) from The HSE Coach Resources section.

Common Mistakes to Avoid

- Relying solely on PPE.

- Ignoring higher-level controls due to cost or time.

- Not reviewing controls after incidents.

- Implementing multiple low-level controls instead of one effective high-level one.

- Lack of training on correct PPE use or engineering systems.

Tip: The best safety systems focus on eliminating hazards, not managing consequences.

Real-World Example — Concrete Cutting Operation

| Hazard | Control Measure (By Level) |

|---|---|

| Dust Exposure | Substitution – Use wet cutting methods. Engineering – Local exhaust ventilation. Administrative – Rotate workers. PPE – Dust mask, goggles. |

| Noise | Engineering – Soundproof enclosures. Administrative – Limit exposure time. PPE – Earplugs. |

| Electric Shock | Engineering – Use ELCB breakers. PPE – Insulated gloves, boots. |

Each control builds on the next, reducing risk layer by layer.

Internal Links

- How to Prepare a Risk Register for Construction Projects

- How to Conduct an Internal HSE Audit | Checklist Included

- Safety Walkthrough vs Safety Audit

- Construction Site Risk Assessment: Key Hazards and Controls

- Common Mistakes in HIRA and How to Avoid Them

External References

Conclusion

The Hierarchy of Controls provides a clear, logical path for controlling hazards — from eliminating risks entirely to using PPE as the final safeguard.

By applying these five levels in order, organizations can significantly reduce incidents, protect workers, and build a proactive safety culture.

“Control the hazard at its source — not at the worker.”

Start applying the hierarchy today, and make safety a built-in part of every job, not an afterthought.